There is a debate in the construction and operations world that refuses to die:

Is purchasing the same as supply chain management?

It’s a bit like asking whether coffee is the same as caffeine closely related but certainly not identical. Let us get things straightened out.

Purchasing and supply chain management go hand in hand, though they are linked to the success of any project differently. Purchasing is as simple as what, how much, and where the transactional aspect of it is. This includes: planning, sourcing, delivery, and logistics. Once the deal is made, the Other party makes sure that the deal goes through the entire chain of a transaction. Here is the Important reason why such clarity is important;

Why does this distinction matter?

According to Gitnux, 79% of companies with high-performing supply chains achieve above-average revenue growth.

That’s not the nudge; that is a billboard saying Get your supply chain act together. Whether you are running a warehouse with fixtures or trying to balance lead times of HVAC units, the key to knowing the difference between these two functions can break or break your bottom line; they are no longer opponents. They are members of a team.

What is Purchasing in Business Operations?

Particularly in construction and infrastructure, purchasing is the starting point. It is the function that ensures the right materials are ordered, vendors are engaged properly and the project stays within its financial boundaries. In other words, purchasing entails processes such as making orders, changing prices with suppliers, and receiving the ordered materials at the right time and in the right quantity.

More, however, lies behind the surface. It is not only a question of who can also provide the lowest price, but it is a question of how the whole process of supply chain and purchasing can be controlled in a way that supports the project timeline, profitability, and the expectations of the clients. The action of any business largely depends on purchasing to kickstart the operations of the business.

The Two Sides of the Purchasing Coin

- Tactical purchasing is all about the day-to-day dealings, taking immediate orders, resolving availability problems, preventing the project schedule derail, making the delivery, etc.

- Strategic purchasing looks ahead. It entails matching purchases with project projections, creating long-term ties with suppliers, and calculating the total cost of ownership, which involves not only price but also quality, secure delivery, and long-term influence on the business.

Omni Build Pro’s Role in Smarter Purchasing

At Omni Build Pro, we know that buying is not a job alone but a competitive advantage tool as well. This is why our solutions are developed to improve supplier relationship management and streamline the purchasing process to decrease delays and over expenditures. Our clients achieve smarter decisions at every step, going from reactive to predictive purchasing models.

According to NumberAnalytics, Predictive analytics in procurement leads to 15% better pricing and 12% lower storage costs.

Why Proactive Purchasing Matters?

When the purchasing system is both proactive and not reactive, you are no longer desperately cutting costs; you are generating them. Even education-sector procurement processes are an excellent illustration that purchasing on a limited budget needs meticulousness, forethought, and the right choice of collaboration. Purchasing becomes even more than an operational need when the correct tools and teams are in place to become a performance driver.

Also, Read Our Guide on Explaining Whether Procurement Is The Same As Purchasing!

What is Supply Chain Management?

When it comes to buying, buyers need to make the right choice, but when it comes to management, it is all about supply chain management;

Does the buying work like a clock, across the borders, the warehouses, departments, and available delivery areas and zones?

Supply Chain Management(SCM) plays a larger, more tactical role compared to buying. While purchasing guarantees availability, SCM ensures that items reach the right place at the right time without causing logistical disruptions. It is never the responsibility of a single department. Additionally it thrives on cross-functional coordination across procurement, inventory control, logistics, operations, finance and even marketing.

The Role of Cross-Functional Coordination

Inefficiencies are accumulated in silos when such functions are tasked with working independently. However, when they are combined, the optimization begins. The thing is that supply chain and purchasing management cannot be interchangeable, yet they are interdependent. It is futile to make good buying decisions when your supply chain cannot match.

We are creating supply chain solutions that integrate with your procurement strategy well, providing you with real-time visibility, improving forecasting, and flexible planning abilities. Alignment is key, whether it is a high turnover flow of materials or Multi-site construction projects. To provide you with a little bit of a global perspective: In one of the logistics projects at a hospital,

According to arXiv from 32% to 23% Hospital logistics in Tanzania reduced stockouts with centralized Supply Chain Management.

Why Strong SCM Matters Across Industries?

It is one good case of how good SCM will determine the difference between going out of inventory or cruising things. Other industries, such as Healthcare, are taking the front line in reorganising their healthcare procurement workflows in order to enhance resilience and minimise operational gaps. And construction and infrastructure are not much behind. When your supply chain is as well-oiled as a machine, all other aspects, such as budgeting to client delivery, fall into place.

Core Differences Between Purchasing And Supply Chain Management

Supply chain management and purchasing are not twins; they are more like brothers and sisters with wildly different personalities, though they are mostly discussed as one.

Let’s break it down:

| Aspect |

Purchasing |

Supply Chain Management |

| Role |

Acquiring goods. |

Managing the entire flow from supplier to end-user. |

| Scope |

Transactional: ordering, invoicing, vendor negotiation. |

Strategic: Sourcing, logistics, production, delivery. |

| Tools |

Vendor databases, procurement software, Purchase orders. |

Supply chain Platforms, analytics, forecasting tools. |

| KPIs |

Order accuracy, cost savings, vendor lead time. |

Delivery times, Cross-functional efficiency, inventory turnover. |

The main distinction is between the focus and scope. When one speaks of purchasing, one is focusing on what we need to buy and who we need to buy it through, but in the area. Supply chain management one is taking a broad look at the flows of goods, where the goods are stored, and how rapidly they are delivered without any hitches.

Lean Supply chain approaches are one such means through which such differences manifest themselves in the actual world, using Just-In-Time (JIT) purchasing, to be precise. Instead of keeping materials in stock for weeks, companies now coordinate the purchasing in manufacturing.

According to Wikipedia, JIT purchasing in manufacturing reduced inventory levels from 47 days to just 5 days.

That is not reducing costs; that is efficiency engineering.

At Omni Build Pro, we are closing the gap between strategy and implementation. Our team understands that purchasing rarely happens in perfect conditions. Whether you are coordinating FF&E and OS&E procurement packages or managing projects with multiple contractors and delivery points, we build systems that connect purchasing with a lean, responsive supply chain. Since buying and SCM work together, you are not only getting materials, you are gaining momentum.

👉 Also, Read Our Guide on: Difference Between Procurement and Supply Chain.

How They Work Together in Real Projects

Think of purchasing and supply chain management as the left and right hands of a well-run project distinct functions that must move in perfect coordination. One orders, the other makes sure that everything around the order is alright. When carried out properly, it is not only efficient but also profitable. However, in a practical project cycle, purchasing plays an essential role in the larger supply chain management plan. It is normally applied following the selection of sourcing agencies and the selection of vendors. Then the process of purchasing to payment starts, purchasing units can send POs, follow up on deliveries, and manage invoices, simultaneously remaining on schedule and to cost, which is monitored by SCM.

We do not implement these functions as silos at Omni Build Pro. This comes with our integrated project delivery, specifically on FF&E hospitality projects, whereby our supply management team is hand in hand with purchasing since the beginning. Be it marbling countertops or global shipment of lights, we work with our teams to evaluate vendors, shipping schedules, and budget restrictions, as in the hospitality development, a delay in delivery means a delay in opening doors.

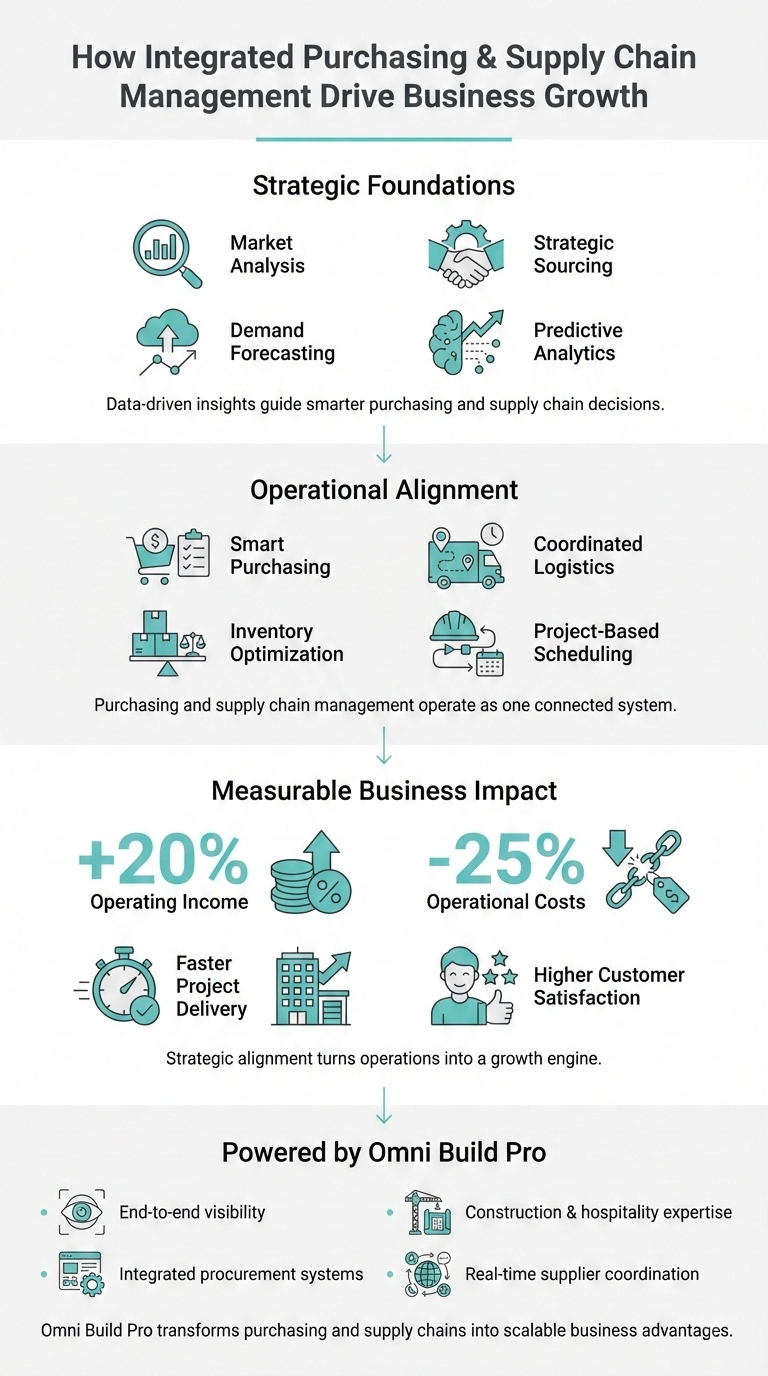

How Market Analysis Supports Both Roles

The combination is even greater when supported by market analysis. Monitoring the movements of the prices of materials, changes in the prices of freight, and vendor performance will assist purchasing teams as well as SCM teams to better make the call. It helps to plan supply chains more easily. As an example, early access to seasonal price falls or geopolitical disturbances makes proactive purchasing possible, and dramatic effects can be the outcome.

According to SDI, a part distributor in the U.S saved 5.5 million every year and reduced its operations costs by 25%, just through digitizing its supply chain. It is precisely that kind of visibility and control that we install in our systems with clients.

Procurement for Hotel Development and the Importance of Timing

Similar plans are used in the procurement for hotel development, where accuracy in procurement strongly impacts the opening dates and the ROI of investors. It is all interrelated. A single purchase on time and a single slip can put an entire chain of supply at a standstill. Summing up, collaboration of purchase and supply management does not work in a chain but rather in tandem, thus delivering more than just materials and schedules. It provides you with control, clarity, and cost-effectiveness all in one lean system.

Strategic Impact & Business Growth

When accomplished, purchasing and supply management is not merely a back-office process: buying and supply management is a growth engine. This is true; they put your materials in supply and your shipments out. But their true superpower lies in customer satisfaction, targeting accuracy, and enabling a company to grow in a smarter and safer way.

I guess we should begin with strategic sourcing. It does not mean picking the most affordable vendor, but it means that you should pick partners who share your plans. Quality standards and delivery schedules. Add to that some strong market analysis, and you stop responding to the changes in the supply chains; you foresee them.

How Strategic Sourcing Strengthens Downstream Processes

In a flash, the orders that your purchasing team used to make have put the business in a position to avoid risks and pursue opportunities. As a synchronised system, purchasing and supply management enhance all that comes downstream:

- Forecasting is less risky, hailed by demand insights and supplier information.

- The number of satisfied customers has increased since delays have been reduced and the availability of products has been enhanced.

- Risk mitigation moves from reactive to proactive; you are able to see what is going on in the market, and the performance of your suppliers is watched on a real-time basis.

👉 A good example?

Electronics distributors have combined their purchases and SCM activities with predictive analytics and supplier dashboards. They also reduce their net promoter score NPS from 20 to 70, in addition to reducing the lead times. They would not only be a supply win, they would be a business transformation.

Our team has experienced the same outcomes. In relation to the procurement support for office setups, we are not only offering assistance with the provision of the tables and the chairs, but we also determine the procurement relying on the vendor strategy, production according to the sequence, and inventory by project requirement and project workspace.

The result? The work completed earlier, on budget, and with the bare minimum of mess.

What about the ROI?

According to Gitnux, companies that improve supply chain efficiency by just 10% can see a 20% boost in operating income. And it’s not a small improvement, it’s a game-changing leap.

At the end, it is the strategy that succeeds. When your supply and buying systems communicate with each other and make informed decisions that are aligned, it not only supports the business. They assist it to grow.

Final Thoughts

At this point, it can be understood that international purchasing and supply chain management are two different but closely related pillars of operational success. Purchasing controls what and when to buy while supply chain management oversees how, where, and when materials flow through the system.

To recap:

- Purchasing is a transaction process; it brings the goods in.

- The supply chain management is strategic; it maintains the entire system moving.

In combination, they all facilitate forecasting, cost control, rational optimisation of inventory, and customer satisfaction.

But what’s the actual difference?

They occur when you no longer do the ticket box check mark, but rather combine them as you go through your project life cycle. Deciding what hotels to build, equipping offices, or coordinating multiple construction phases in your project, due to the coordination of supply chain management and purchasing, easier planning, fewer surprises, and improved financial results can be achieved.

At Omni Build Pro, we have spent years delivering seamless purchasing and supply chain support across industries. Our team is not only familiar with these functions; we design systems that integrate them using real-time insights, supplier coordination, and fast agile logistics so that projects stay on schedule. Whether you have your sights set on an improved end-to-end procurement strategy, we can assist you, turning the current state of chaos into a controlled situation without anyone making a fuss in the process, one shipment at a time.

Frequently Asked Questions

Q1: What is the role of purchasing in supply chain management?

The Purchase constitutes a crucial, ground force in supply chain management. It concentrates on buying materials and services through which operations are carried out. This involves making orders, communicating with the vendors, and also the quality of goods one receives. Purchase also contributes to the logistics, as the deliveries are arranged according to project schedules because even excellent planning may fall to pieces, as the materials are bogged down without arriving or arriving in the wrong condition.

Take, for example, a multi-site office arrangement where the purchasing crew guarantees the furniture orders are delivered in the right order according to the development of the work on interiors. In the absence of such a sync, there are disruptions in the supply chain flow and project timeline, or a hit.

Q2: How does Purchasing differ from procurement and supply chain?

It is confusing to mix them up, but they have a different purpose:

- Purchasing is operative, taking Orders and invoices, and delivery of goods.

- Procurement is more extensive, encompassing the process of selecting a vendor, negotiating, and observing contracts.

- Supply Chain management is strategic and operational, which deals with the movement of goods, information, and services in the entire process linking the sourcing to the final delivery.

Consider the analogy: Procurement chooses what to purchase, buying makes the purchase, and SCM ensures that all transports easily to the finish line.

Q3: Can a company have purchasing without supply chain management?

Yes, technically, it is kind of light to construct a house with no plumbing. You may sound material through the door, but with the absence of supply chain management, you become exposed to delays, overstocking, failure to meet deadlines, and dissatisfied customers. SCM makes sure that everything is optimised for timely deliveries, vendor coordination, inventory control, and budget alignment. In the absence of it, things are needed reactively, not strategically. But that is a very quick way to become efficient.

Q4: What are the key responsibilities of a purchasing manager in the supply chain?

A purchasing manager is an important person in the process of connecting the procurement strategy with the operations. The major duties are;

- Selection and assessment of suppliers.

- Negotiation of cost and contract.

- Monitor of delivery schedules and coordination of logistics.

- Assurance quality requirements and regulations.

- Configuring purchases to make the work phase and inventory demands.

They act as the glue between contracts with vendors and operations on the sites, balancing the cost and making sure that nothing is delayed by a lack of a certain part of the delivery.